The technology behind consumer 3D printing is essentially the same as the technology behind larger additive manufacturing machines used by manufactures.

What’s truly different is that these printers have gotten much smaller, and therefore much cheaper. If you’d like a simple explanation of how these amazing machines work, read on.

Consumer 3D Printing Then vs. Now

Traditionally 3D manufacturing was done through a process called subtractive manufacturing. This entailed taking a solid block of material and cutting out the object piece by piece. Think of it like carving a statue. This process is still used, but is seen as a much more wasteful process than the additive manufacturing process.

The additive process revolutionized how things are made by laying down microscopic layers of material layer by layer until the object is “printed”. Consumer 3D printing devices use this technology, but on a much smaller scale.

The additive process revolutionized how things are made by laying down microscopic layers of material layer by layer until the object is “printed”. Consumer 3D printing devices use this technology, but on a much smaller scale.

Materials

In the beginning of the three dimensional printing boom, there were only a few materials available that could be used. Now that the technology has advanced, and the resolution of these printers has gotten better, there are many materials that can be used to print 3D objects. Things such as plastics, paper, rubber, metals, just to name a few can be used to craft objects.

Costs

Consumer 3D printers are getting really affordable. On the low end, for printers used to print toys and small parts, you could get a printer for as little as $1500 or less. For larger items, and for printers that can handle mass scale, you’re looking at more hefty prices.

Professional mid-range models can cost anywhere from $10,000 to $20,000. On the high end of the scale you’re looking at around $600,000 for heavy duty printers.

Obviously the higher end machines are still out of reach for most consumers, but given that those high end devices cost well over a million dollars just a few years ago, you can see how the prices have come down.

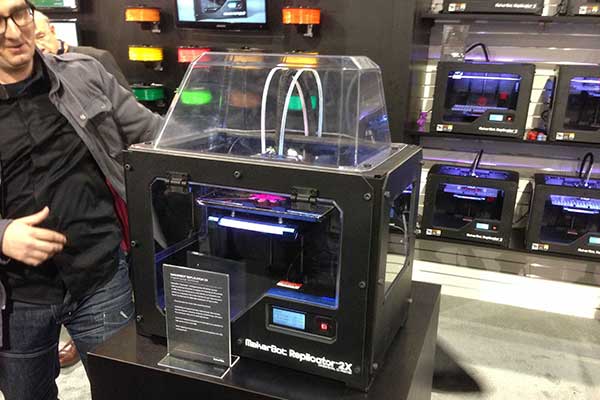

The most popular of these consumer 3D printing devices is called the MakerBot. It comes in two different models, which differ in resolution and material opportunities.

The reason why they have become so popular, especially amongst the hobbyist crowd, is because they can use many materials and are fairly cheap.

You can pick one up for less than $2000, and that comes with everything you need to get started.

Last year alone the industry saw $2.2 billion dollars in sales. As the technology gets cheaper and more advanced, consumers will begin to take advantage of these printers for household manufacturing and entrepreneurial endeavors. Consumer 3d printing will one day be as its 2D counter-part.