3D printing technology is rapidly changing; one area experiencing the most change is the size and cost of printing materials. For a lot of consumers, 3D printing is still a mystery. You might’ve read about 3D printing in Wired, or somewhere online, and wondered what it’s all about and how it works. One of the technologies used in 3D printing is called Stereolithography or SLA. What is SLA 3D printing and what is it used for?

What SLA 3D printing Is

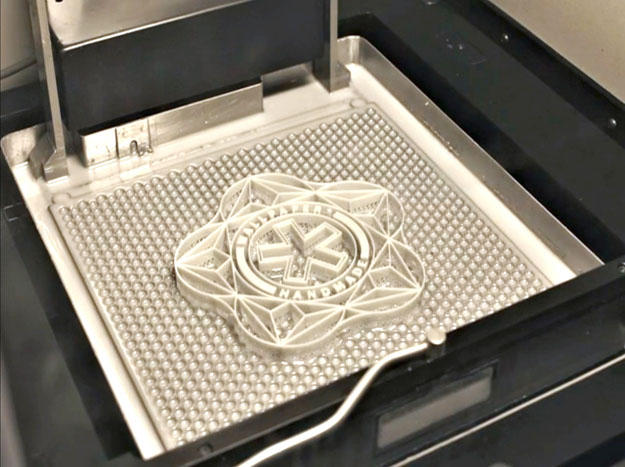

Understanding what is SLA 3D printing will not be difficult. SLA 3D printing is an additive 3D printing process that uses a liquid ultraviolet resin, and a laser to build 3D objects layer by layer. The laser traces the pattern of the object onto the resin, which cures and solidifies each layer. That process also joins the layer to the layer below.

After the entire object is traced, the printer’s elevator platform descends layer by layer, as a resin filled blade goes across the traced pattern, and re-coats the object with a fresh layer of resin.

The new layer is traced, with the same process, until the object is whole. After the process is complete, objects are put into a chemical bath to get rid of excess resin. They are then put into an ultraviolet oven to be cured further. The whole object has to be supported with supporting structures, which holds the object together as it is printed. These supports can be removed after the object is finished.

What Is SLA 3D Printing Used For?

As you can tell, SLA 3D printing is a really involved process that takes a lot more than a 3D printer. Most consumer 3D printers use filament nozzles, which lay down heated filament layer by layer. That process is much different than SLA 3D printing, and much less expensive. SLA printers can range between $100,000 and $500,000. Each litre of resin can cost up to $210. There are a couple of consumer SLA printers out there, but they cost a lot more than a printer like the MakerBot Replicator 2.

The objects made by SLA 3D printing are usually parts for manufactured goods, and are often use for prototypes. These prototyped parts can be used to test products before they are put into mass production.

SLA 3D printing is relatively fast. Objects, which can be up to 20 cubic inches, can be made in less than a day. Consumer printers usually take several hours to make objects much smaller than that.

The prototypes that come out of this process are really strong, too, which means they can be used in machines. SLA 3D printers are also much more accurate than other, more affordable, 3D printers.

The obvious disadvantage is cost. Since the printers and resin costs so much, most consumers aren’t looking at this type of printer for home use. FormLabs has promised an SLA printer for under $4000.