A Simple Guide to Upgrading 3D Printer Extruders

After working with your 3D printer for a while, you may notice a number of problems with your extruder. It may skip, get clogged, or produce increasingly worse results with stringing and blobs of filament throughout your model. Whether you need a new cold end, hot end, or nozzle, we have you covered with this quick guide to upgrading your 3D printer extruder.

The Anatomy of an Extruder

There are three distinct parts that make up a 3D printer’s extruder: the cold end, the hot end, and the nozzle. Here’s a brief description of each component:

The Cold End

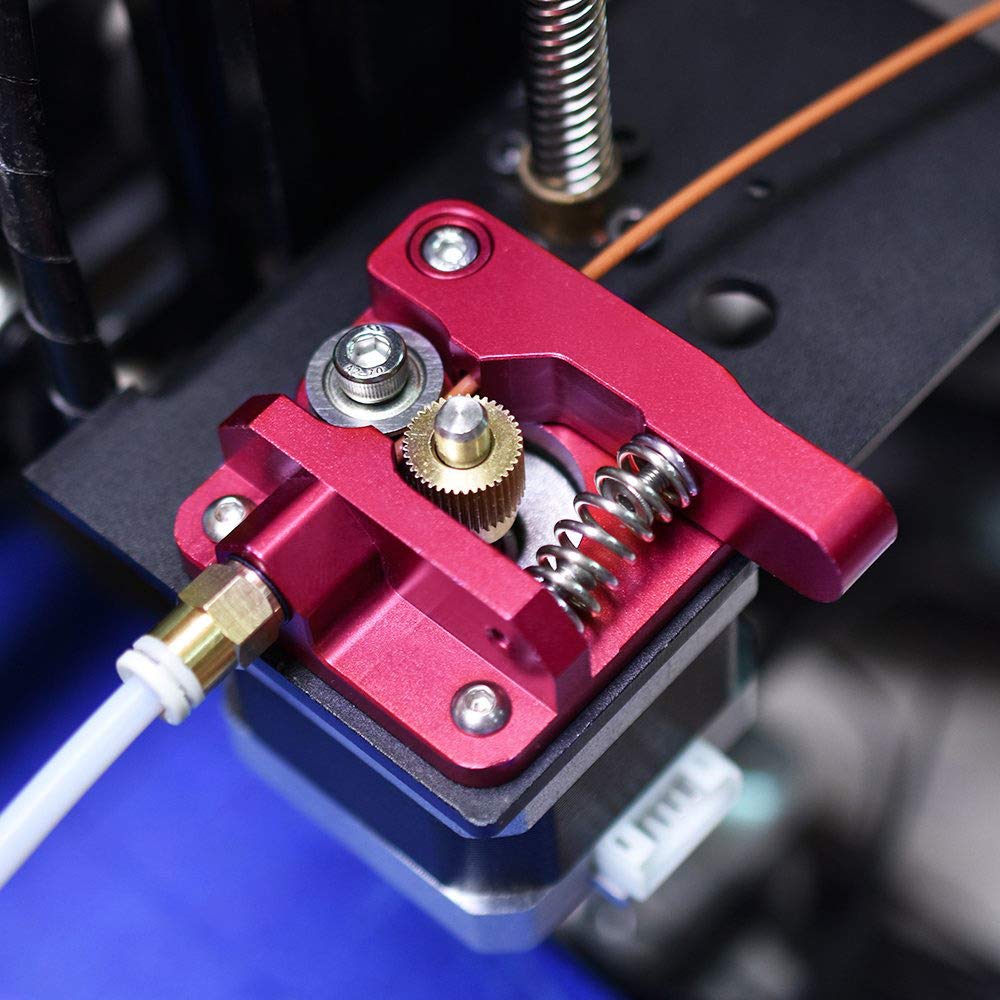

The cold end is the part of the extruder used to drive filament into the heated portion of the extruder (the hot end). Sometimes, this piece is simply referred to as the extruder, though for the purpose of this article, a 3D printer’s extruder encompasses both hot and cold ends.

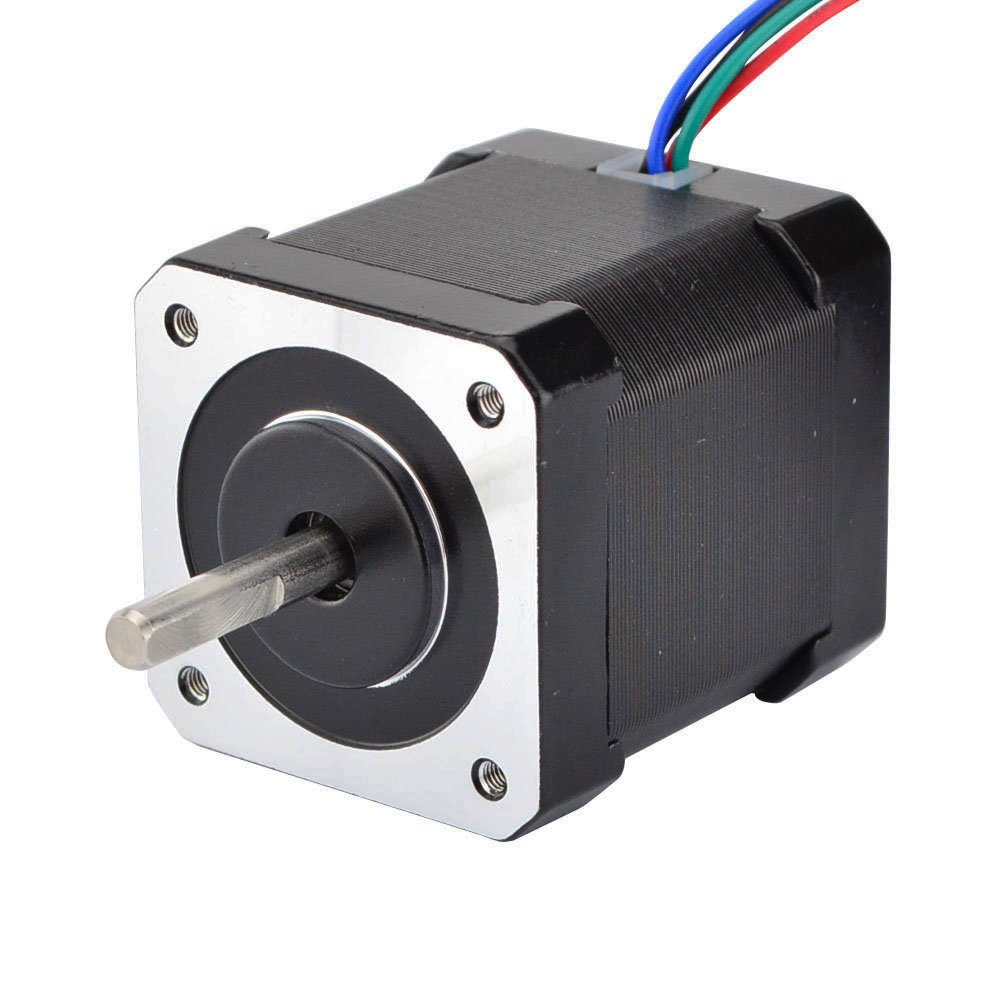

The two most important components include the stepper motor that drives filament at a consistent rate, and the hobbed bolt or shaft that grips filament and keeps it in place during extrusion. There are two main types of cold end setups, including direct- and Bowden-style cold ends.

Direct extrusion simply means that the cold end is located directly above the hot end. In the simplest terms, direct extrusion is good for most filaments, but is particularly good with flexible filaments and retraction.

Bowden extrusion separates the hot and cold ends of the extruder, locating the motor and hobbed mechanism onto the frame of the 3D printer instead. Without the added weight of the cold end, the hot end is free to move more quickly, which aids in printing speed. Typically, most people prefer direct extrusion for its superior retraction and filament compatibility.

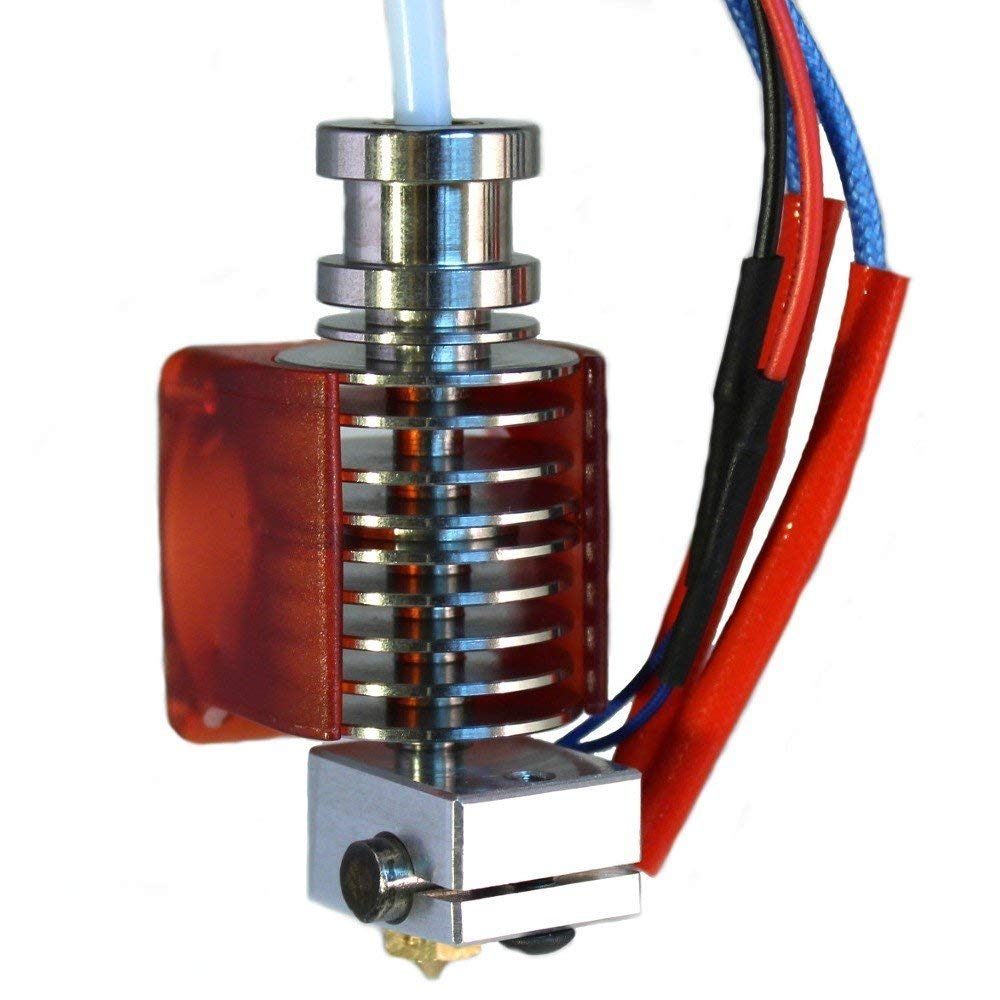

The Hot End

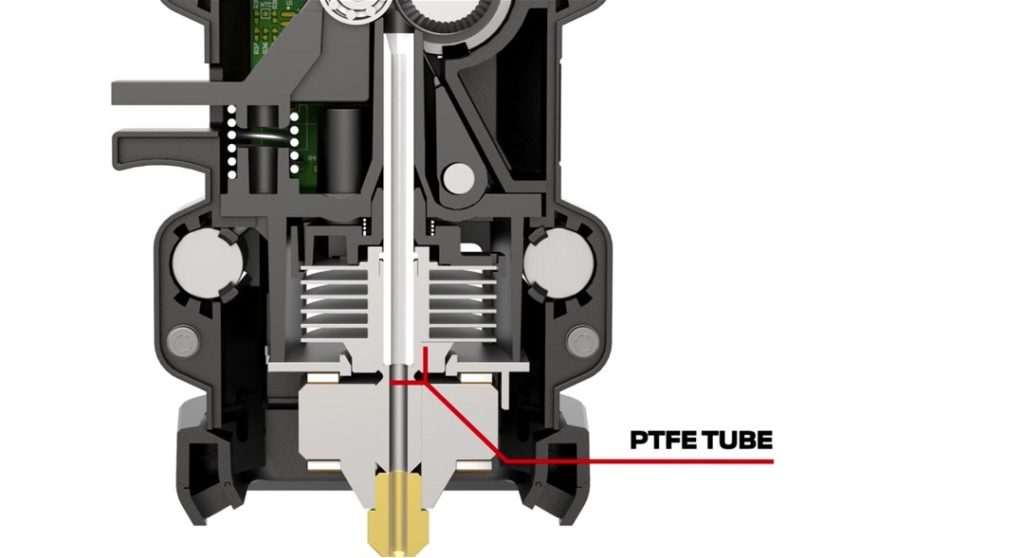

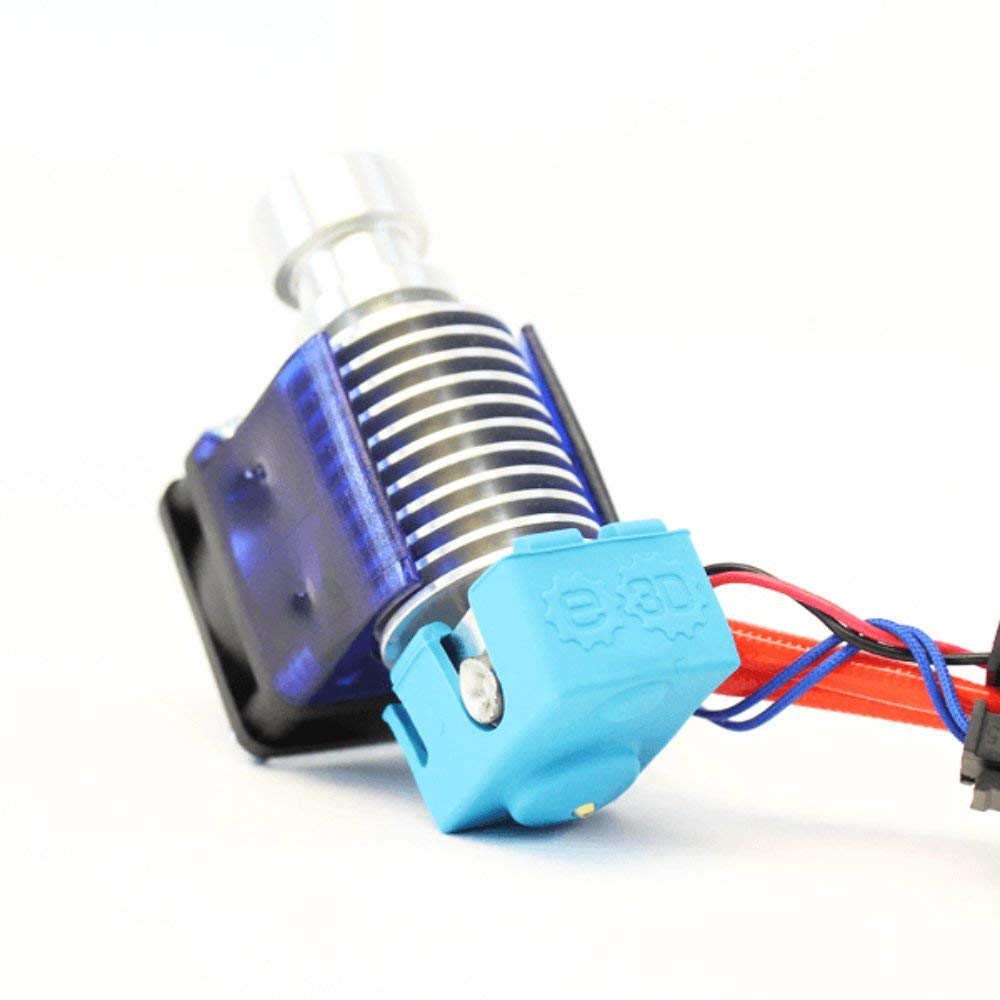

This is where the magic happens. Solid filament controlled by the cold end reaches the hot end, where a number of components heat the filament to liquid form. The heat block, heat sink, thermistor, heater cartridge and a few other components work together to precisely heat your filament to liquid before extruding it from the nozzle. This is also typically where most extruders fall short. If the hot end is lined with insulation tubing, like PTFE, it limits the number of filaments you may use. We discuss all-metal hot ends vs PTFE/PEEK tubing a bit later in the article.

The hot end is the most commonly upgraded part of a 3D printer’s extruder. Upgrading from the stock PTFE hot end that most printers come with to an all-metal hotend or even just a nicer, more precise hot end, makes all the difference in print quality and fixes a lot of problems like clogged extruders and print imperfections.

The Nozzle

Although technically considered part of the hot end, we think nozzles deserve their own category. That’s because nozzles vary widely in quality and performance, and are easier to replace than the entire hot or cold end. The two main points to consider when choosing a nozzle are nozzle-point diameter and construction material. Abrasive or sticky filaments can get easily jammed in a nozzle that’s too small, too large, or made from the wrong material.

When it comes to sizing, consider the layer resolution you’re aiming for, as well as the print speed. A wider nozzle prints thicker layers faster. A thinner nozzle point prints smaller, more refined layers at a slower pace. Be sure to consider filament feed speeds, as well as hot end temperature, when changing nozzle diameters.

The other consideration is nozzle material, and here you have a few choices. The cheapest nozzles tend to be made of brass, and are only really good for use with PLA and sometimes ABS. Moving on, you can find nozzles made from higher grade metals like steel or tungsten carbide, and even nozzles with ruby tips to help withstand printing with abrasive filaments.

Why Upgrade Your Extruder?

Extruders are largely responsible for the quality of your models. A good extruder feeds filament at a steady, controlled rate while maintaining precise temperatures during a print. Print accuracy improves and post processing becomes minimal with a good extruder.

So what should you look for when buying an extruder upgrade? First, make sure the extruder you want is compatible with your machine. Some 3D printers use proprietary extruder setups, while others use common, interchangeable extruder builds. Check the dimensions and electrical compatibility of an extruder before purchase.

Next, look for equipment from a reputable company. It costs more to buy from a brand like E3D or Micro Swiss, but you get what you pay for. It’s not worth buying a cheap extruder upgrade only for it to work the same or worse than your stock extruder.

Finally, one of the most important things to consider about an extruder is whether it uses PTFE/PEEK tubing or if instead it’s all-metal. In most 3D printers under $1,000, the stock extruder maxes out at temperatures around 250C, limiting the number of filaments you can use.

Temperature limitations mainly come down to the PTFE or PEEK tubing inside. This tubing helps filament move more smoothly through the extruder and keeps filament from sticking to the walls of the extruder. That makes PTFE perfect for low-temperature applications like ABS, PLA, and TPU. Unfortunately, both PTFE and PEEK degrade over time and require replacement. Temperatures above 250C are also ill-advised, since this is the temperature at which PTFE begins to soften.

Upgrading to an all-metal hot end fixes these issues. With an all-metal hot end, you’re free to print in high-temperature filaments like Nylon or PC. You also don’t need to replace the tubing, or worry about it degrading and messing with your prints.

Does everyone need an all-metal hot end? Absolutely not. If you primarily print in PLA, for example, there’s no real benefit to all-metal vs PTFE. On the other hand, if you’d like to experiment with more filaments and dislike the idea of performing regular maintenance on your hot end, it’s worth the change. Of course, even if you stick with PTFE tubing, accuracy and precision can always be improved with a higher-quality extruder.

Cold End Upgrades

Need or want to replace your cold end? Its job is simple, but when a cold end doesn’t work properly you get serious extrusion issues. Here are some cold end upgrades to check out, though there are plenty more on the market:

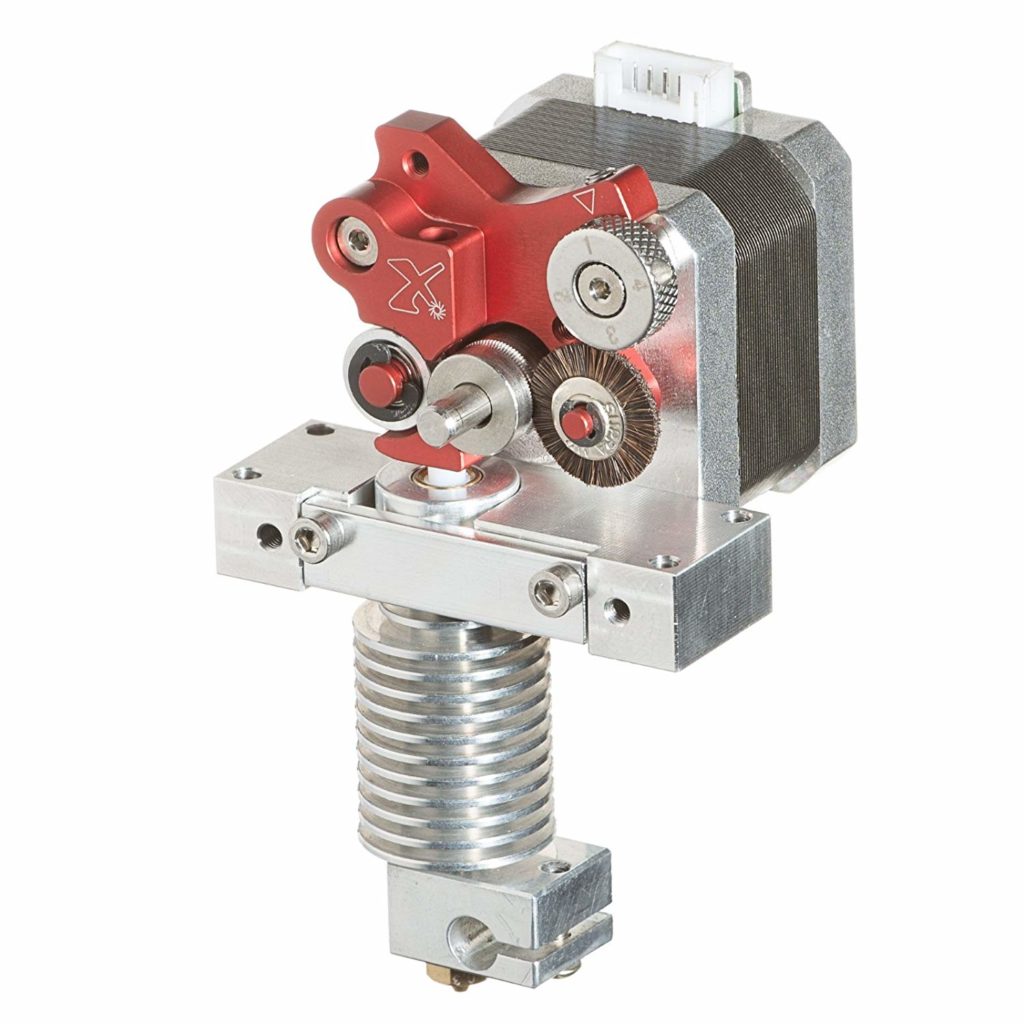

Bondtech BMG Extruder

Aokin 3D Printer Parts MK8 Extruder Upgrade Replacement

GEEETECH Extruder Aluminum Feeder Kit

Nema 17 Stepper Motor Bipolar 2A 59Ncm

Hot End Upgrades

Stock hot ends are just that- stock! They’re rarely the best products you can buy. Whether you want an all-metal or PTFE-tubed extruder, there’s an upgrade out there for you.

Genuine E3D V6 All-Metal HotEnd

Micro Swiss All Metal Hotend Kit for Creality CR-10 / CR10 / CR10S / Ender 2 / Ender 3 Printers .4mm

Genuine E3D Titan Aero 1.75mm Standard 12V

Genuine Diabase Flexion-E3D

Nozzle Upgrades

Replace your old, worn nozzle or buy a set of nozzles in different diameters to fill out your collection. Higher quality nozzles won’t really improve your print quality, but they will last longer and cause fewer problems.

AUSTOR 13 Pieces Stainless Steel 3D Printer Nozzles

Genuine E3D Hardened Steel Nozzle V6

Micro Swiss High Lubricity Wear Resistant Nozzle Upgrade MK10

PrimaCreator PC-NSP-04Hx1-MK10

Extruder Tools

3D Printer Nozzle Cleaning Kit

3D Printer Nozzle Cleaning Tool Kit