Dual extruders: what are they, how are they used, and are they worth the high price manufacturers ask for them? This article will answer all your burning questions so you can decide if you need (or just want) a 3D printer with dual extrusion.

Dual Extruder Basics

At the moment, dual extruders are a simple upgrade to single extrusion. With dual extrusion, two nozzles share the same head and move as one piece. For this reason, 3D printers with dual extruders do not print twice as fast as printers with single extrusion. In order for that to be true, each nozzle would have to move independently without interfering with the other. Once you imagine that logistical nightmare, you understand why dual extrusion is still limited.

Don’t be discouraged, though! Dual extruders have much more to offer than simply speeding up print time. Both hobbyists and professionals can both appreciate the benefits of dual extruding 3D printers.

How Are Dual Extruders Used?

Support Filaments

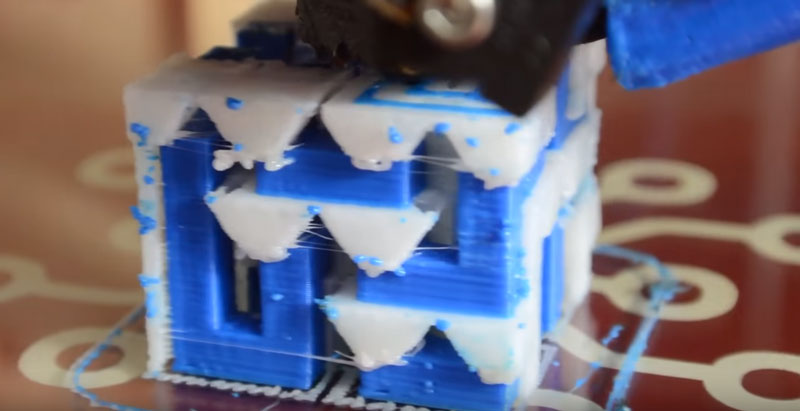

The ability to print with support filaments is arguably the most common and useful function of dual extrusion. One nozzle is loaded with your main filament while the other nozzle sits ready with HIPS, PVA, or other dissolvable filament for support structures.

Support Filaments are needed when:

- You’ve been printing supports in the same material as the item you’re printing, and are sick of all the work you have to do in post to get the item presentable.

- You’ve been avoiding certain prints because they require supports and you don’t want to deal with the problem above.

- You’ve never used a 3D printer before, but need one to print geometrically complex items or simply want the freedom to build whatever models strike your fancy.

Printing in Two Colors

This function is pretty self explanatory. With a single extruder, getting two colors into a single print is a chore and a crap shoot. You have to stop the print, remove the filament, reload the new color, and hope the two bond once printing resumes. What a pain.

Dual extruders make the whole process much simpler and more reliable.

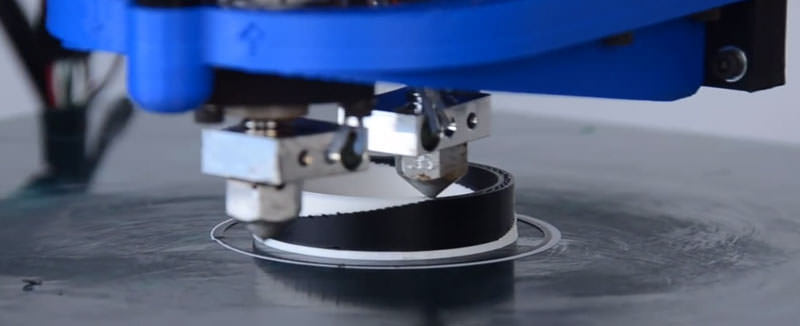

Multiple Small Part Printing

Mass printing small parts is an underrated function that both hobbyists and professionals should keep in mind. Small items that are identical and do not exceed the width between both nozzles can be printed simultaneously.

This is a very specific feature that not everyone can utilize, but that helps save time for applicable prints.

Do You Need a Dual Extruder?

For most people, single extruders are still a fine choice. This is especially true for beginners, since dual extrusion adds another layer of complexity to printing. For example, oozing becomes a problem, and slicing gets a big more complicated.

On the other hand, just about everyone can benefit from dual extrusion. Dual extrusion allows you to make more interesting, gravity-defying models with the help of support filaments. Dual extrusion also makes it much easier to create multi-colored prints. If these features are important to you, it’s worth saving up for the added cost of a 3D printer with dual extrusion.

If you’re interested in a 3D printer with dual extrusion, check out our reviews of the Airwolf 3D HD2X and Leapfrog Creatr XL. Kits are also available for enterprising DIY-ers who want to upgrade their current 3D printer.

Top 8 3D Printer Comparison Guide 2017

| Picture | Name | Printing Speed (mm/s) | Supported Filament(s) | Price | Rating (1-10) |

| LulzBot Taz 6 | 200 | PLA / ABS / HIPS / PVA / Wood / Nylon / Polycarbonate… | $$$ | 9.0 | |

| Sindoh DP200 3DWOX | 200 | PLA / ABS | $$ | 8.3 | |

| FlashForge Creator Pro | 30 – 160 | ABS / PLA / PVA | $$ | 8.1 | |

| Bibo2 Touch 3D Printer with Laser Engraver | 80 – 120 | PLA / ABS | $ | 8.0 | |

| UP Mini 2 | 100 | PLA / ABS | $$ | 7.8 | |

| FlashForge Finder | N/A | PLA | $ | 7.6 | |

| QIDI Technology X-One | 150 | PLA / ABS | $ | 7.5 | |

| New Matter MOD-t | 80 | PLA | $ | 7.5 |