When we first encountered 3D printing as a new technology, our first reaction may have been as simple as “Awesome! I want to try that!” But after gaining a grasp of the basics, the focus naturally shifts to optimizing.

Experimenting With Settings

Part of that optimization process involves experimenting with a printer’s settings to learn what will yield the best results. For example, if your objective is to create a fast prototype and forgo the fine details, learning to set a lower vertical resolution will optimize your use of the printer for this purpose.

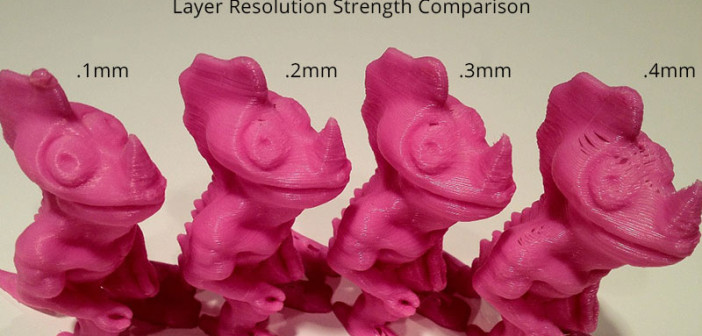

Vertical Resolution and Strength

Now, while it’s understood that decreasing vertical resolution will also decrease completion time, such a consensus has not yet been reached for the correlation between resolution and structural strength.

Does increased vertical resolution create a stronger print?

To Answer this question, let’s take a look at a few of the factors that affect a print’s strength.

Layer-To-Layer Adhesion

One aspect that we must consider when discussing a print’s strength is layer-to-layer adhesion. If the layers of filament do not adhere well to one another, the completed part will not be strong.

The real question is, assuming that all other setting have been optimized, what layer height will create the best layer-to-layer adhesion?

High Resolution Heat Transfer

Printing in high-resolution (and let’s make 100 microns our high resolution standard here) may yield increased strength due to increased layer-to-layer adhesion. Why would high-resolution improve adhesion?

Well, higher resolution equates to finer layers, and while a finer layer may cool faster because of its thinness, it can be evenly reheated as the nozzle passes over it again to apply the subsequent layer.

The heat applied to the previous layer, together with the heat of the newly applied layer, will allow for good layer-to-layer adhesion, which translates to a stronger finished print.

High Resolution Surface Area

Another point to consider here is surface area. How much of the previous layer’s surface directly bonds with the subsequent layer?

Let’s say, for this example, that your printer is utilizing a .4mm nozzle, and you’ve set your layer height at 400 microns. The surface area where layer one and layer two meet will be minimal since the extruded filament will have a rounder shape. This makes the layer-to-layer bonds weak, leading to a weaker print overall.

However, using that same nozzle with a layer height of 100 microns will create more of an oval shape, with the top and bottom being flatter, meaning that the surface area where layer one and layer two meet will be greater and allow for greater layer-to-layer adhesion. This will create an overall stronger finished print.

Other Strength Factors

While these are some points regarding the relationship among resolution and print strength, there are several other factors that affect a prints strength, such as layer orientation and infill density and design, so if creating a strong print is a priority be sure to take a look at these factors as well.