When it comes to consumer-grade 3D printing, there are three common types to consider: FDM, SLA, and DLP. Today we break down the differences, similarities, and pros and cons of each 3D printing method.

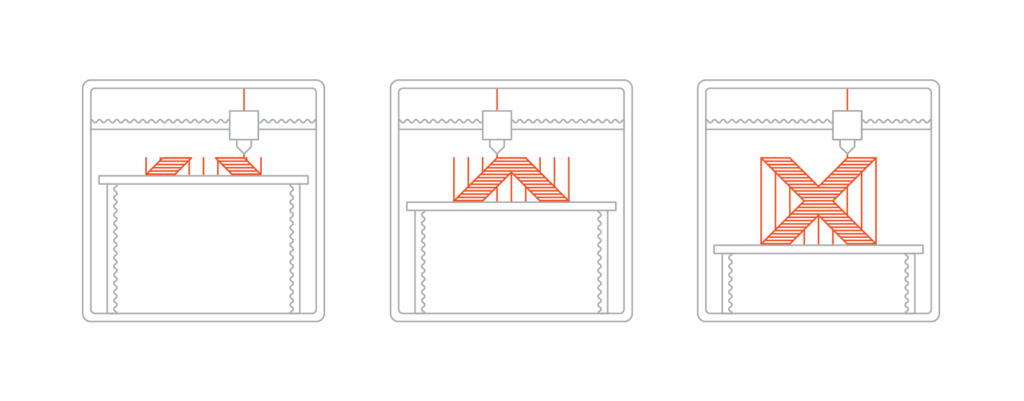

FDM (Fused Deposition Modeling)

FDM is the most common and cheapest form of 3D printing. This method works by extruding melted filament layer by layer to form complete models. The filament solidifies a few moments after being extruded but before the plastic fuses to the layer below. FDM printing allows you to print in a wide variety of materials ranging from nylon to ABS.

FDM 3D printers are available for every budget with prices ranging from $150-2,500. While some FDM printers achieve incredible accuracy and smooth results with limited visible layering, FDM printing is largely considered the least perfect results. That’s because most FDM printers produce models with varying degrees of visible layering. FDM models also tend to require more post processing to fix imperfections. Still, due to its affordability and relatively low learning curve, FDM printing remains the most common form of consumer 3D printing.

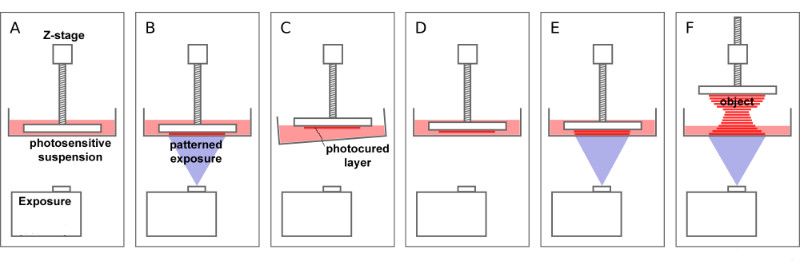

SLA (Stereolithography)

Despite being the very first 3D printing technology, SLA printers are less common than FDM due to their relatively high cost and high maintenance. SLA printing works by shining a laser at precise points within a vat of resin, curing the resin in place and creating a model one “pixel” at a time. Although the laser moves rapidly, SLA printing is still slower than FDM printing.

On the other hand, SLA printing is much more accurate. Resin cures with literal pinpoint precision, resulting in air- and water-tight models with no visible layering and improved isotropic integrity when compared to FDM models. That’s why SLA 3D printing is championed by industry professionals who require high accuracy and ultimately, usability in their models. Obviously, these same characteristics are appreciated by home users, too. Dealing with resin may be messy, but for some the near-perfect results are worth the added effort and expense.

SLA printers can be found for as little as $200, but be aware that the build volumes on cheap consumer models are very small. Not all SLA printers are created equally, either, meaning that cheap SLA printers are more likely to malfunction or produce subpar models. Good, cheap SLA printers start around $400-500.

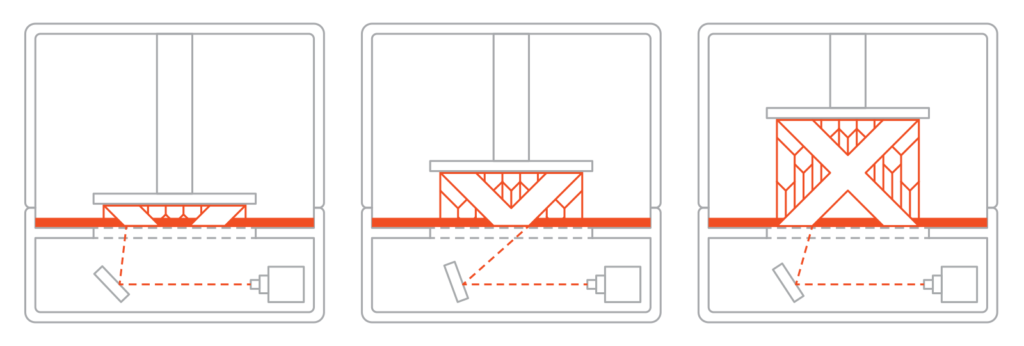

DLP (Digital Light Processing)

DLP printing is actually just a sub-type of SLA. Both use vat polymerization technology, which is a fancy term for curing resin with light. While traditional SLA uses a laser to cure resins, DLP uses a projector screen to flash light into the resin vat from below. The difference is that SLA cures resin one point at a time, whereas DLP cures resin one layer at a time by projecting an entire layer at once into the vat. In this way, DLP creates models by applying one layer on top of the other like FDM printing.

The results of DLP printing fall somewhere between SLA and FDM. DLP models are smoother and tend to have better isotropic integrity than FDM models, yet fall short of the perfectly-smooth, minutely-detailed results of SLA models. The problem is that DLP printing depends on the resolution of the projector screen, meaning it works better with smaller models than large ones. With larger DLP models it’s not unusual to see block pixelated edges and fine visible layering. These problems can be fixed with simple post processing, but note that they are non-issues when it comes to SLA.

DLP 3D printers start at about $300 and go into the thousands. Like SLA printers, cheap DLP printers come with very small build volumes. Notably, DLP printers also tend to be larger than SLA printers, and larger than FDM printers by print volume.

Which Type of 3D Printer is Right for You?

It’s good to know your options when shopping for a new 3D printer, but which type should you choose? For most people reading this, an FDM printer provides the best bang for your buck. Not only do you get a larger print volume, FDM printers are relatively low-maintenance compared to SLA or DLP. That’s because vat polymerization requires you to handle toxic uncured resin, which can be time consuming and messy. You also must cure completed models after removing it from the build plate. By comparison, FDM printer only require you to load the filament spool. Models from FDM printers do not require additional curing, however they do need more post-processing to achieve perfection.

For others, the quality from SLA and DLP printers justifies the additional cost and maintenance. If you want highly precise models with smooth surfaces, SLA is the premier choice. SLA is more expensive and the printing process is slower compared to DLP or FDM, but SLA currently produces the most flawless results. If you want or need the best in 3D printing, SLA is for you.

DLP 3D printing represents a solid middle-ground between the affordability and convenience of FDM and the unparalleled results of SLA. On smaller scales, DLP even matches the quality