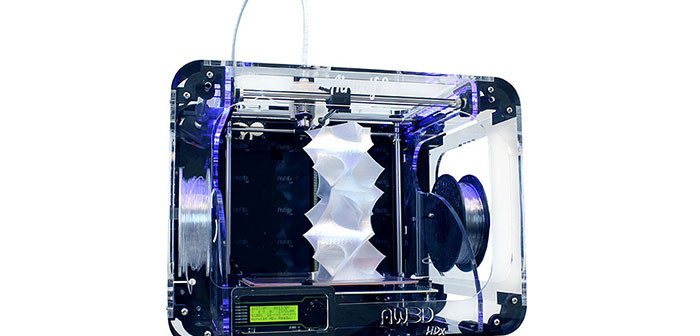

Costa Mesa, California-based company AirWolf 3D has introduced a new 3D printer that is set to ease the wallets of engineers and designers by providing a means of prototyping with high-grade materials that does not carry the hefty price tag of traditional fabrication machines. What’s the new alternative? The AW3D HDx.

Usable Filament Types

This printer can extrude a large variety of materials from engineering grade materials such as nylon and polycarbonate, to traditional materials such as ABS and PLA.

JRx Hot End & High Temperature Printing

The AW3D HDx features the patent-pending JRx hot end, which is jam resistant and can reach the high temperatures required for printing with high-grade materials like nylon and polycarbonate. In fact, the printer can sustain temperatures of up to 599° F.

AW3D HDx Features

The printer, which is an upgrade from the current AW3D HD, comes with a ton of great features and upgrades. The build platform is an expansive 1,150 cubic inches (12” x 8” x 12”) and can print with a layer resolution as high as 60 microns. It can also print with a positioning precision of 20 microns. Best of all, it can fit on a desktop.

AirWolf 3D Vision

For Erick Wolf, founder and CEO of AirWolf 3D, it’s all about “the creativity it could unleash as engineers and artists experiment and create objects…that were virtually impossible to affordably print.”

Production and Price

AirWolf 3D printers are manufactured within the United States, in the company’s Costa Mesa, California facility, and the company is still able to offer the AW3D HDx for $3495, hundreds or even thousands of dollars cheaper than competitors.

And while it will take time before 3D printers become a common household item, AirWolf is certainly doing their part to “bring imagination to the desktop.”