If you are asking the question “what is 3D printing?” the answer is simple. It is a common prototyping and small form manufacturing process where a machine called a 3D printer uses a 3D design file to create a real world object.

3D printing is used in many situations by both hobbyists and professionals alike. In the last few years it has gained momentum in the consumer market as well.

The way the process works is by sending a 3D .stl file to the printer.

The 3D printer then takes that file and uses it to “print” a real world object layer by layer. 3D printers can use any number of materials from plastics to rubber.

3D Printing Technologies

3D printers come in three different forms. First is SLS or Selective Laser Sintering. The second is FDM or Fused Deposition Modeling. And the third is Stereolithography or SLA. Below is a brief description of each process.

SLS

Selective Laser Sintering involves the use of a high power laser that fuses material powder into a 3D object. The reason why it is selective sintering, is that the laser selectively fuses the powder layer by layer via a cross section scan. After each scan and fuse, the powder bed is lowered a bit so the next layer can be laid over top.

FDM

Fused Deposition Modeling involves the use of a plastic filament or metal wire, which is them melted down and dispersed by a nozzle. The machine uses the STL file to lay down the material layer by layer.

SLA

Stereolythography is the process by which a liquid ultraviolet resin and a laser build 3D objects layer by layer. The laser beam traces out the 3D object on the surface of the resin. The exposure to the ultraviolet light of the laser fuses each layer to those previously carved out.

After the 3D pattern has been traced by the laser, the elevator platform which holds the resin descends layer by layer as a resin filled blade carves out the object from the pattern the laser traced out. As the blade carves, it lays down a fresh coat of the resin material. The final step is to soak the object in chemicals to remove the excess resin.

Which technology is used depends mostly on cost and size of the object.

3D Printing Applications

There are many uses for 3D printed objects, with more applications being invented every day. One of the biggest growth areas for 3D printers is in the medical industry, where doctors and dentists use 3D printed objects to design and print out objects for use in medical procedures. Instead of having to wait weeks for a new crown or denture to come in, they simply design and build it right in the object in a few hours. This saves time and money both for the dentist and the patient.

Doctors use 3D printed objects to model replacement parts for bones and ligaments. This makes it easier for them to show the patients exactly what is being done during a procedure.

Other applications outside the medical realm include jewelry, art, architecture (3D modeling), fashion and interior design.

How Does 3D Printing Work?

No matter what technology the 3D printer uses (See above), the basic theory behind the process is essentially the same. A 3D file is created on a computer using something like AutoCAD, and is fed to the 3D printer. Most consumer 3D printers then takes that file and uses some form of material to build a 3D object layer by layer. This process is known as the additive process. This means it creates an object out of nothing. The subtractive process is where a 3D object is carved out of a solid block of material.

As the printer lays down each layer, the layers fuse together to form the 3D object. This means that the smaller each layer is, the more precise the design can be. This is called resolution. Consumer printers can print layers that are 100 microns thin, and these layers are getting smaller with every new generation of 3D printer.

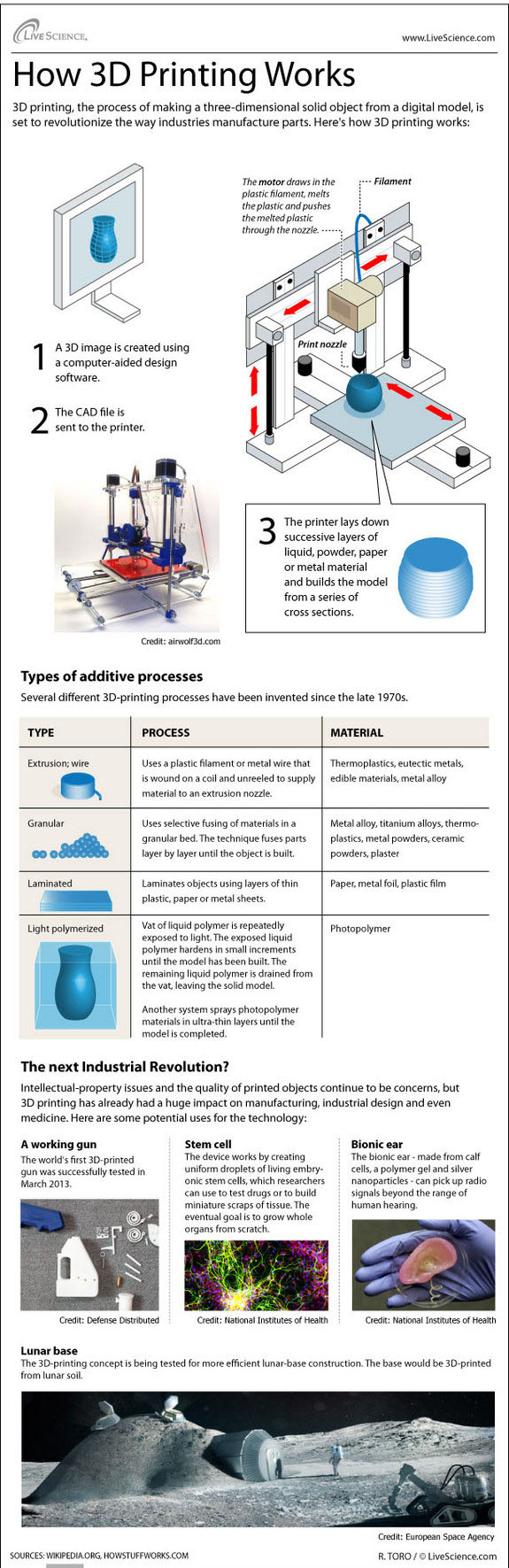

Infographic

Source:LiveScience

What Can You Make With a 3D Printer?

The sky is the limit when it comes to what you can do with a 3D printer. Well, maybe not the sky, but your imagination is the limit, so maybe that’s a bit higher. With consumer 3D printers like that from Makerbot, you can produce common household replacement parts like screws, jewelry, toys for the kiddies, and pretty much any other relatively small object that you can draw. Most consumer 3D printers are limited to solid objects that can be produced in one piece. That means printing something like a computer or mp3 player would necessitate manufacturing skills outside of the 3D printer.

More advanced parts, and bigger builds still need to be done by industrial 3D printers. There are services online that let consumers and hobbyists design objects that need these industrial printers.

The Average Cost of a 3D Printer

If you’re looking into buying a 3D printer, there are many consumer focused options out there. These range from $1000 to about $8000. There are, of course, more expensive 3D printers on the market that consumer can buy if they have the coin.

Industrial 3D printers can range from $10,000 to a whopping $600,000. These printers are obviously a bit out the range for most consumers, and even if they can afford them, would be too big to fit in most homes or garages. They also often require advanced computer software beyond the 3D software available to consumers.

What Materials Can a 3D Printer Use?

3D printers can use many different materials to do their work. These include, but are not limited to the following materials:

- Plastics and Polymers

- Polyamide (AKA Nylon)

- Glass

- Resin for SLA (stereolythogrpahy)

- Silver

- Titanium

- Steel

- Wax

- Polycarbonate

- Photopolymers

As 3D printer technology advances, more and more materials are included in that list. Most printers are limited to one or two materials for a single object. As the technology advances, 3D printers will be able to print with several different materials at the same time.