Beauty is in the eye of the beholder. The 3D design of the product you want is not always available for download. Though there are more than hundreds of thousands of models available for 3D printing. The solution to this problem is to hire a designer to design the model from scratch or use a 3D scanner.

How 3D Scanners Work

Prior to 3D printers, molding and casting, injection molding and other types of manufacturing processes were used to produce desired objects. These manufacturing processes involve contact with a molding material and the molds are sometimes destroyed in the process. 3D scanning is a non-contact and non-destructive technology. 3D scanners use optics to create digital models of physical objects.

3D scanners use a laser, a sensor and imaging software to digitize an object. The object is illuminated with the laser which is then reflected according to the surface of the object. The reflected light is then picked up by the sensor. The sensor used in general is a CMOS sensor. By using triangulation principles, the distance between the source of the laser and the point of reflection (the surface of the object) is calculated.

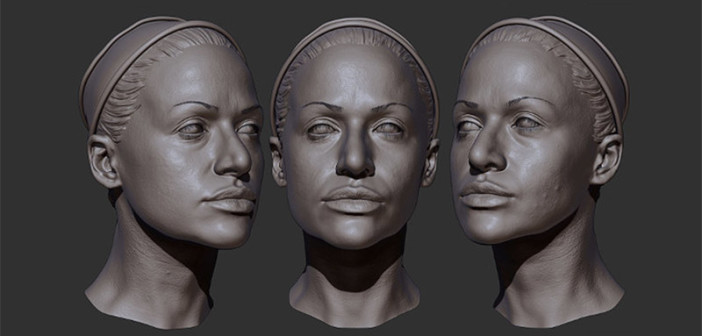

Using this data, software collates the distance of all points on the surface of the object to the source of the laser to digitally re-create the surface of the scanned object. The object is rotated around itself or the scanner is rotated around the object to create a three dimensional image of the object. The technique used for distance measurement is the same as that of a RADAR. There are also other more complex technologies that are growing in popularity.

Drawbacks of 3D Scanners

The accuracy of the digitized image depends on a variety of factors, many of which are inherent to the technology used for scanning. The accuracy hinges on distance being measured accurately between the source of the laser and the surface of the scanned model. A lot of the accuracy depends upon an accurate reflection of the laser which in turn depends upon the angle of surface.

All digital systems involve a fundamental process called sampling. The higher the sampling rate, the higher the accuracy and size of the data recorded. High amount of sampling also entails higher consumption of time taken for scanning. This translates to a trade-off between accuracy of the scan to time taken for the scan. As with any electronic system there is an existential risk of introduction of noise during the scan process, which in turn gets transferred to the digitized 3D model and the scan is sometimes not print ready.

Choosing A 3D Scanner

Cost of 3D scanners vary according to resolution, precision and maximum scan height. 3D scanners are available in a wide range of prices. The price variation is due to the technology used, along with their precision levels and scan sizes. 3D scanners are available in portable hand held types too. The right choice for your 3D scanner depends upon your required precision for scanning along with maximum scan size.

Conclusion

An alternative to creating a digital 3D printable file manually is to perform a 3D scan of an object. Precision, scan time, scan size, and cost are a few factors which are considered when purchasing a 3D scanner. Find the right 3D scanner for you and you’ll be ready to print.