Buying the right FDM 3D Printer is easy once you know what to look for. As you may know, FDM is short for Fused deposition modeling. This is the most common consumer 3D printer you can buy. Here we look at the key factors to consider when choosing the right FDM 3D printer for you.

FDM 3D Printers Explained

An FDM 3D printer uses Filament applied layer by layer to create 3D objects in the physical world. Objects can be printed using a wide variety of filament materials. These printers can print using filaments such as Plastic, which is the most common, to woods, and even some metals.

Now let’s take a look at exactly how to choose the best FDM 3D Printer.

Buy the Best FDM 3D Printer

There are a few key specs to look for when buying a consumer 3D printer. Here they are listed below in no particular order. All are important in there own right. What you plan to make with your 3D printer will help you figure out the most important spec for your needs.

- Build Area

- Printing Speed

- Supported Filament Types

- Connectivity Options

- Layer Resolution

- Nozzle Diameter

- Extruder(s)

The area where the printer prints the 3D objects, also called the “build area”, determines the 3D printed objects maximum size. This is less impoartant for those wanting to print object like jewelry. A 3D printer’s maximum build area is more important for rapid prototyping uses.

If you like things fast, then the time it takes for your 3D object to print is important to you. The printing speeds of consumer 3D printers has a wide range. So it is key that you look for an FDM 3D printer’s maximum printing speed when buying one.

The filament that is available for your 3D printer will determine what materials you can 3D print. For Example, if you want to 3D print using a wood or even glass.

How you plan to connect your 3D Printer should be considered. Take a look at your space and think about how you will connect, and which connections you have.

The layer resolultion is the thickness of each layer of filament that is applied during 3D printing. This helps to determain the 3D printed object’s strength.

When buying a 3D printer, you may want to consider the size the extruder nozzle. The extruder nozzle diameter is the size of the hole that the filament flows out of when 3D printing.

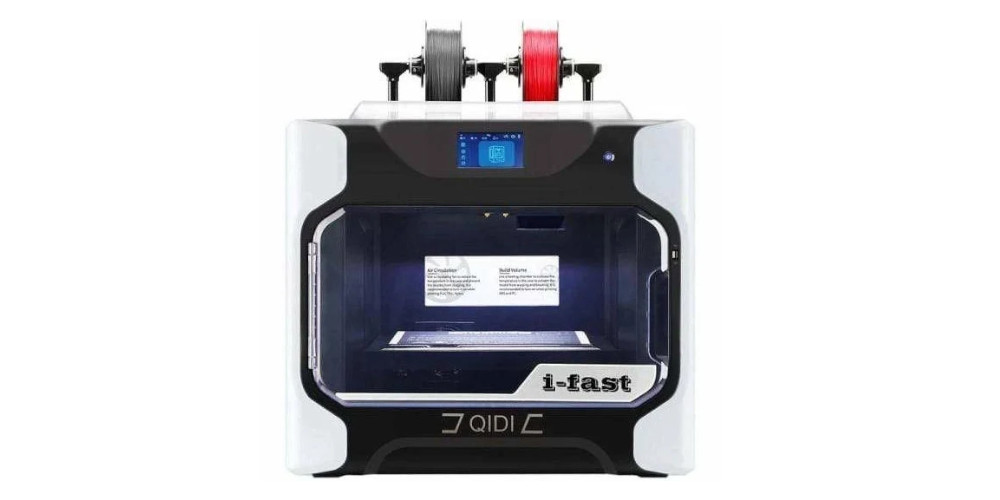

multiple extruders on your 3D printer will allow you to print using more that one filament at once. This very important went printing detailed complex designs that may require a support filament. Multiple extruders also allow you to 3D print objects using multiple colors.

Top 8 Consumer FDM 3D Printer Comparison Guide 2017

| Picture | Name | Printing Speed (mm/s) | Supported Filament(s) | Price | Rating (1-10) |

| LulzBot Taz 6 | 200 | PLA / ABS / HIPS / PVA / Wood / Nylon / Polycarbonate… | $$$ | 9.0 | |

| Sindoh DP200 3DWOX | 200 | PLA / ABS | $$ | 8.3 | |

| FlashForge Creator Pro | 30 – 160 | ABS / PLA / PVA | $$ | 8.1 | |

| Bibo2 Touch 3D Printer with Laser Engraver | 80 – 120 | PLA / ABS | $ | 8.0 | |

| UP Mini 2 | 100 | PLA / ABS | $$ | 7.8 | |

| FlashForge Finder | N/A | PLA | $ | 7.6 | |

| QIDI Technology X-One | 150 | PLA / ABS | $ | 7.5 | |

| New Matter MOD-t | 80 | PLA | $ | 7.5 |