When Roy Stewart, a surf enthusiast and luxury surfboard designer from Pataruru, New Zealand challenged himself with the task of creating a revolutionary new design that would relieve single-finned boards from the burden of a dolphin-style fin that performed inefficiency, he turned to 3D design and printing technology, a medium which allowed him to explore new possibilities and realize his design goals.

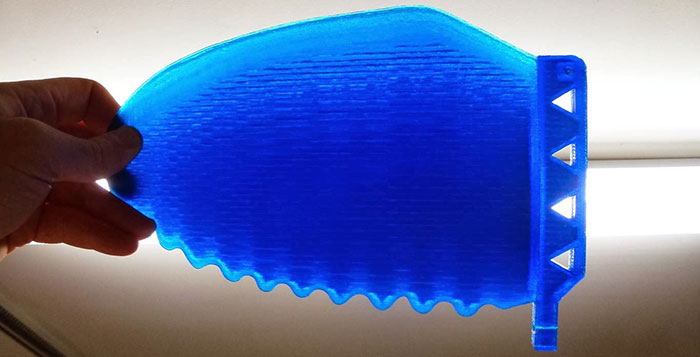

3D Printed Whale Fin Design

During his search for effective design, Stewart looked to the Humpback whale, specifically the aerodynamic construction of its pectoral flippers and the function of the tubercles, or bumps, that are found on their surface.

He had already tested the effectiveness of this design, to some extent, by creating a wooden whale fin: the Warp Drive Spitfire cutaway fin, which he featured on his 10’6” surfboard – Earl.

Wanting to improve on his design further and looking beyond the limitations of wood-crafting (which can require close to 40 hours per fin) and fiberglass molding (which is difficult to work with and expensive) he enlisted the help of 3D printing specialist and designer Andrew Palmer.

With the help of Palmer, Stewart was able to turn his concept into a computer-aided design, which features a hollow core and a bumpy leading edge foil (BLEF) (the texture found naturally on whale flippers), which creates a 40% increase in efficiency by creating water flows which promote improved acceleration and speed, increased lift, greater stability, and decreased drag, all adding up to a smoother ride.

The original prototype was printed using ABS filament and put through rigorous testing for strength. Now, fins are printed using a more durable polycarbonate material in fun, translucent colors, and range in size from 6.5 to 9 inches.

Interested in owning one of these yourself? The prints are priced between $82-$164.